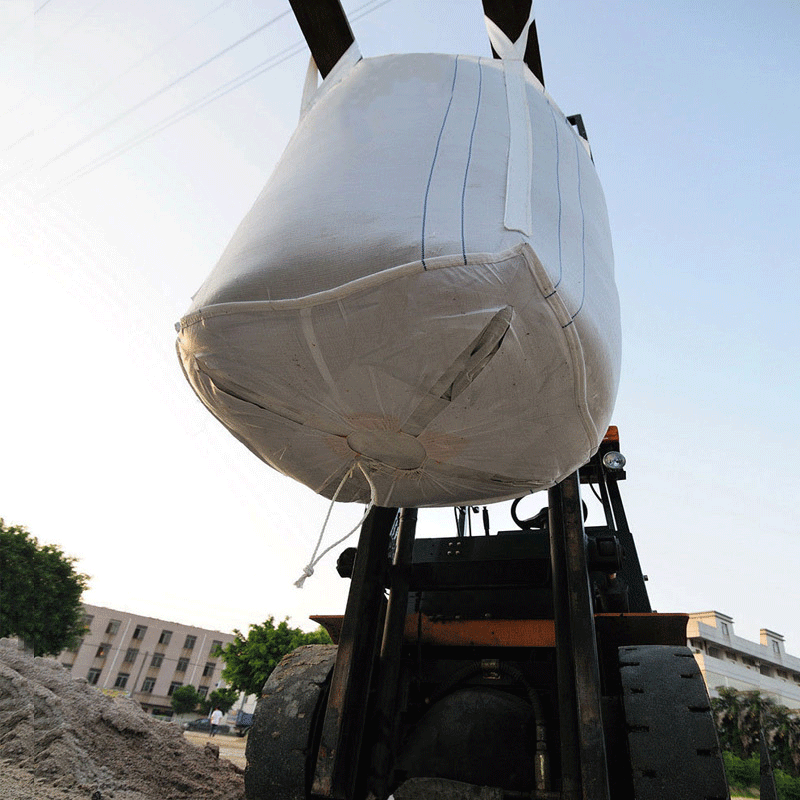

The container bag takes polypropylene as the main raw material, adds a small amount of stable seasoning, evenly mixes, melts and extrudes the plastic film through the extruder, cuts it into silk, then stretches it, makes the PP precursor with high strength and low elongation through heat setting, and then makes the base cloth of plastic woven cloth through textile and film coating, and sews it with suspenders and other accessories to make a ton bag. Container bag products are widely used, especially the powder and granular objects such as cement, grain, chemical raw materials, feed, starch and minerals packaged in bulk, and even dangerous goods such as calcium carbide, which are very convenient for loading, unloading, transportation and storage. Container bags mainly contain massive, granular or powdery items, and the physical density and looseness of the contents also have significantly different effects on the overall results.

Jiahe white big bag has better sealing, higher strength and lower cost. Compared with traditional iron drum packaging, it reduces the transportation cost by more than 10%, the loss of powder is only one tenth, and the economic benefit is greatly improved. Different packaging materials have different sealing requirements. For example, powder or toxic substances and substances afraid of pollution have very strict requirements on sealing performance, and materials prone to moisture or mildew also have special requirements on air tightness. Therefore, when designing container bags, pay attention to the influence of base cloth film covering process and sewing process on the tightness. Bagging usability. When designing container bags, the specific ways and methods of customers using container bags should be fully considered, such as lifting, transportation mode, loading material performance, etc. In addition, we should also consider whether it is food packaging, which is non-toxic and harmless to the packaged food. The quality of container bags is very important. In similar standards at home and abroad, the setting of safety factor is generally 5-6 times. Container bag products with five times safety factor can be safely used for a longer time.

Mianyang Jiahe Packaging Co., Ltd., founded in 2004, is a manufacturer specializing in the production of plastic woven products. After more than 10 years of continuous struggle and development, it has become a large-scale container bag production base in Southwest China. The company has strong technical force and advanced processing equipment. Jiahe company produces various grades of container bags and woven bags (such as ferrosilicon bags, ferromanganese bags, calcium carbide bags, silica powder bags, fertilizer bags, feed bags and other civilian bags). The company has advanced production technology and strong technical force, and has fully passed the certification of ISO9001:2000 quality management system. It is a manufacturer approved by Chongqing entry exit inspection and Quarantine Bureau of the people's Republic of China to produce "plastic woven bag" packaging containers and their production conditions in line with the export commodity quality license system. At present, China's plastic woven container bags (ton bags) are mainly exported to Japan and South Korea, and are vigorously developing the markets in the Middle East, Africa, the United States and Europe. In similar standards at home and abroad, the setting of safety factor is generally 5-6 times. Container bag products with five times safety factor can be safely used for a longer time.

Contact Person:Wang Bo

Email:jiahebaozhuang028@gamil.com 710268394@qq.com