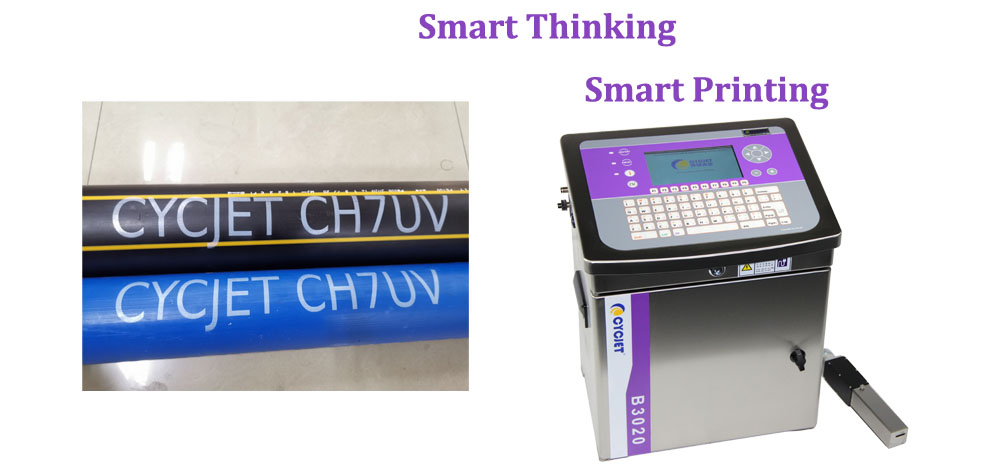

In recent years, with the increasing market demand of construction, municipal engineering, water conservancy engineering, agriculture and industry, the plastic pipe industry has shown a trend of rapid development. At the same time, with the continuous improvement of consumers' quality requirements for product environmental protection, health and durability, etc. While the output of plastic pipe production increases, the product quality level continues to improve, the technological progress of the industry continues to accelerate, and the number of brand-scale enterprises has continued to increase. New materials and new structure varieties are constantly emerging, so this also makes the use rate of inkjet printers in the pipe industry higher and higher. The original pipe manufacturers of printing wheels have been replaced by UV inkjet printers, which not only improves production efficiency, but also to improve the product quality, and further enhance the market competitiveness. Today, I recommend a white ink jet printer suitable for the pipe industry, hoping to help all users in the pipe industry.

First of all, why does the pipe industry use inkjet printers?

The pipe industry and the construction field are closely related. The development of building materials has changed from the initial product form to the current quality form. Many parts, accessories and components need a clear, standard, and networked query and traceability system. When quality problems occur, it can be quickly implemented to manufacturers and people, to find out the reasons, to avoid the appearance of fake and inferior products, and to improve the supervision and monitoring of product quality. Therefore, the pipe industry uses inkjet printers to make pipe products more standardized, transparent and visualized, so that consumers or users can clearly recognize the pipe brand they buy, whether before purchase or during use, they can clearly see common information such as brand model specifications.

Secondly, what is the difference between white ink and black ink jet printers?

When many users consult inkjet printers, they often ignore a crucial issue, which is the demand for ink color. The difference between white and black is not only color, but also the internal structure of the machine and the structure of the nozzle. and price. The price of an imported white ink jet printer is generally 1-2 times that of a black ink printer. In addition to the difference in price, there are also huge differences in the design of the fuselage structure. For example, the ink path structure and nozzles have been designed and adjusted by the printer manufacturer, in order to adapt to the large particles and easy precipitation of white pigment ink to ensure the stability and reliability of the work.

As a pipe factory, how to choose the brand of inkjet printer?

First of all, when choosing an inkjet printer, we must understand the needs of users, how to choose a targeted plan and equipment according to our own product conditions and production line conditions, as well as the existing competing products in the market. For pipe manufacturers, there are many brands of white ink jet printers on the market, so how do you choose the one that suits your company from among the many brands of white ink jet printers? From which aspects should we screen? Today, Shanghai Yuchang will analyze from the following three points to give you some reference.

1. Bare metal price of white ink jet coding machine for pipes.

1. Bare metal price of white ink jet coding machine for pipes.

I believe that price should be the primary consideration for any company. With the fierce market competition and price transparency, the price of an ordinary white ink jet printer ranges from 30,000 to 80,000 yuan. However, as a consumable, the price of white ink is several times that of ordinary black ink. The price of a 1-liter bottle of white ink is about 1,000 yuan to 2,000 yuan, and the price of the corresponding solvent (diluent) consumables is also relatively Higher, about 300 yuan a bottle.

2. The configuration of the special white ink jet printer for pipes.

A good configuration model can make us use more time and life. Manufacturers can make configuration choices according to the needs of the pipe production line, such as the number and height of the proofing font and the speed of the extruder, all of which have a certain impact.

Communication connection will definitely be a development trend in the next few years, from product identification to product life cycle traceability, let the identification generate more value, give each product a unique identity mark, use two-dimensional code to manage product production, manufacture and distribution, realize data-based and visual management, and provide data decision-making basis for manufacturers' marketing.

Therefore, when purchasing, you cannot underestimate the configuration of the inkjet printer. You must buy a model that can communicate online with other intelligent production lines. It must be able to have a communication protocol, including specific instruction information and communication interfaces.

3. Warranty and after-sale service, supply of consumables.

The repair and maintenance of the white ink jet coder is very important. After all, a white ink jet coder is of great value. Therefore, it is necessary to follow the operating procedures of the manufacturer's technical department to make the repair and maintenance of the jet coder more standardized. Secondly, the price of white ink is also very high. Generally, a bottle of 1000ML white pigment ink costs more than 1000 yuan. Therefore, it is necessary to plan the overall use plan before purchasing, regardless of hardware or software, including warranty maintenance.

After we have more understanding and knowledge of the selection and price of the machine, we can quickly choose the inkjet marking equipment suitable for our factory from many brands and models of inkjet printers, so that every pipe, whether it is PPR\PVC\PE or other materials can form a complete system, which helps us to better trace and find the marking scheme.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 16 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Keywords :

High-resolution inkjet printer

Small character inkjet printer

Working video: