The structure of hydraulic cylinder is various, and its classification methods are also various: according to the motion mode, it can be divided into linear reciprocating motion type and rotary swing type; According to the action of hydraulic pressure, it can be divided into single acting type and double acting type; According to the structure, it can be divided into piston type, plunger type, multi-stage telescopic sleeve type, gear rack type, etc; According to the installation form, it can be divided into pull rod, earring, foot, hinge shaft, etc; According to the pressure grade, it can be divided into 16MPa, 25MPa, 31.5Mpa, etc.

Piston type

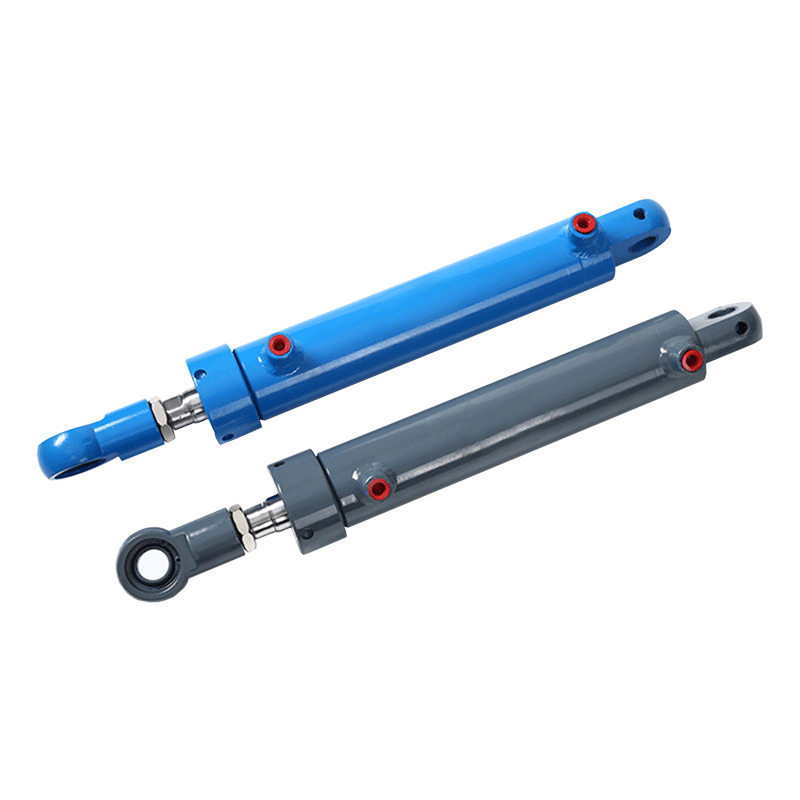

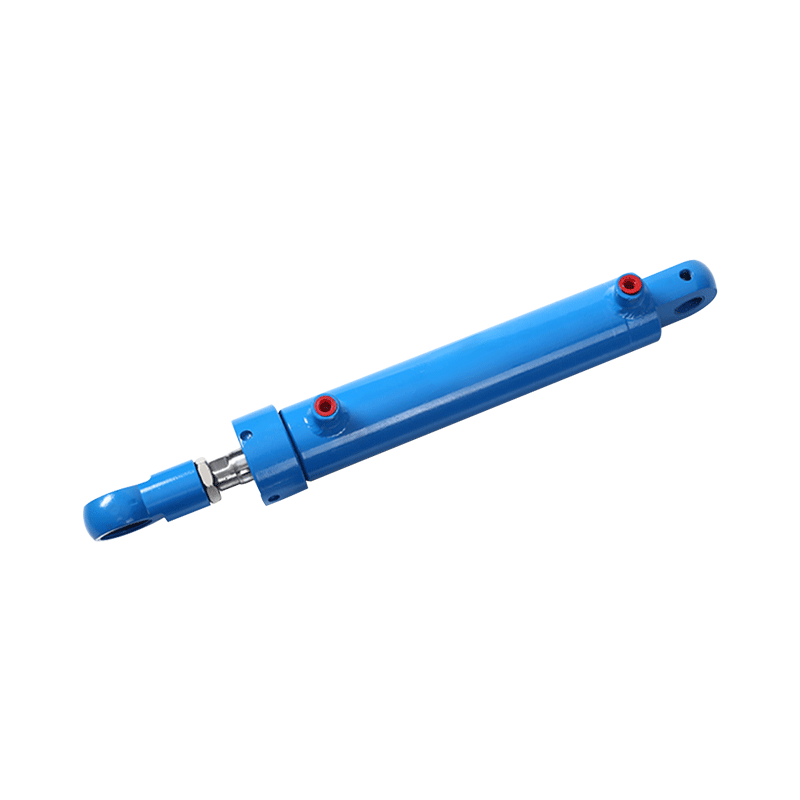

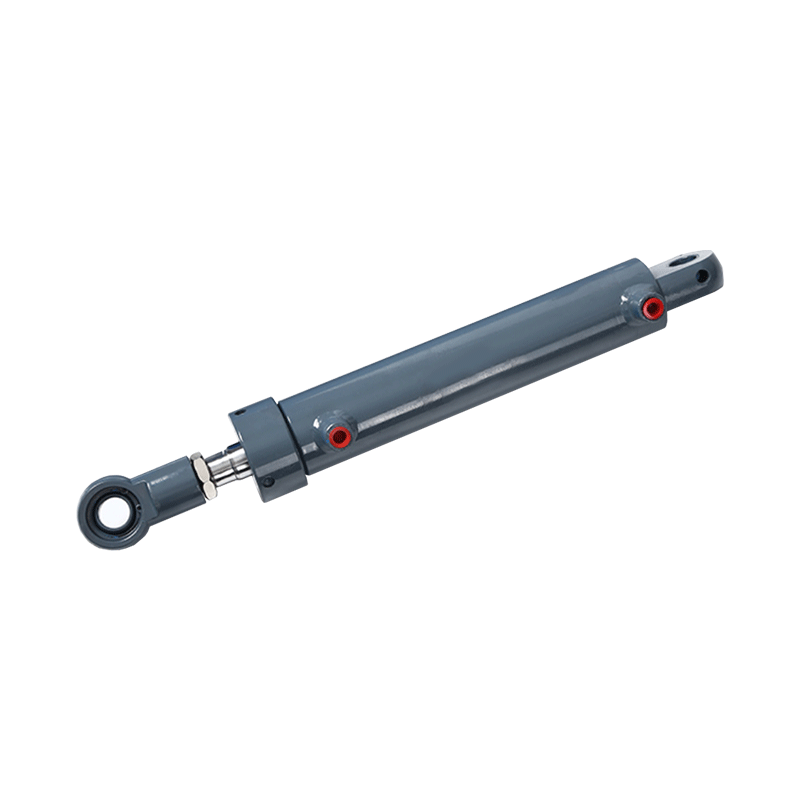

A single piston rod hydraulic cylinder has a piston rod at only one end. As shown in Figure 1, it is a single piston hydraulic cylinder. The inlet and outlet oil ports a and B at both ends can be supplied with pressure oil or return oil to realize two-way movement, so it is called double acting cylinder.

The piston can only move in one direction, and its reverse movement needs to be completed by external force. However, its stroke is generally larger than that of piston hydraulic cylinder.

Piston hydraulic cylinders can be divided into single rod and double rod structures. They are fixed by cylinder block and piston rod. According to the action of hydraulic pressure, they can be single acting and double acting. In the single acting hydraulic cylinder, the pressure oil is only supplied to one chamber of the hydraulic cylinder. The hydraulic pressure makes the cylinder move in one direction, and the reverse movement is realized by external forces (such as spring force, self weight or external load); The movement of the piston in two directions of the double acting hydraulic cylinder is completed by the action of hydraulic pressure through the alternate oil inlet of the two chambers.

Plunger type

(1) The plunger hydraulic cylinder is a single acting hydraulic cylinder, which can only move in one direction by hydraulic pressure, and the return stroke of the plunger depends on other external forces or the self weight of the plunger;

(2) The plunger is only supported by the cylinder liner without contact with the cylinder liner, so the cylinder liner is very easy to process, so it is suitable for making long stroke hydraulic cylinders;

(3) The plunger is always under pressure during operation, so it must have sufficient rigidity;

(4) The weight of the plunger is often large. When it is placed horizontally, it is easy to sag due to its own weight, resulting in unilateral wear of the seal and guide. Therefore, its vertical use is more advantageous.

Telescopic

Telescopic hydraulic cylinder has two-stage or multi-stage pistons. The sequence of piston extension in telescopic hydraulic cylinder is from large to small, while the sequence of no-load retraction is generally from small to large. The telescopic cylinder can achieve a long stroke, while the length is short when retracted, and the structure is compact. This kind of hydraulic cylinder is commonly used in engineering machinery and agricultural machinery. There are multiple pistons that move once. When each piston moves step by step, its output speed and output force change.

Hydraulic cylinder is the executive component in the hydraulic transmission system. It is an energy conversion device that converts hydraulic energy into mechanical energy. The hydraulic motor realizes continuous rotary motion, while the hydraulic cylinder realizes reciprocating motion. The structural types of hydraulic cylinders include piston cylinder, plunger cylinder and swing cylinder. The piston cylinder and plunger cylinder realize reciprocating linear motion, output speed and thrust, and the swing cylinder realizes reciprocating swing, output angular speed (speed) and torque. In addition to single use, hydraulic cylinders can also be combined with two or more or with other mechanisms. To perform special functions. The hydraulic cylinder is simple in structure and reliable in operation. It has been widely used in the hydraulic system of machine tools.

Sichuan Hanbo Hydraulic Machinery Co., Ltd., with the tenet of "specialty and focus" and the characteristics of quality, technology and R & D, has formed the technical services of hydraulic system and components (hydraulic cylinder, valve, joint), cold and other static presses, as well as the design and manufacturing of accessories and dies, precision machining of mechanical parts, environmental protection treatment equipment and technical services. It is oriented to mechanical automation and green environmental protection users, and provides applicable, high-quality Products and technical services with appropriate prices.

From the very beginning, quality, technology and R & D have been featured in our services, providing customized hydraulic machinery, hydraulic system, hydraulic cylinder and hydraulic valve for users, which has become the basic guarantee for the success of users' hydraulic projects. Our products include hydraulic stations, servo electric cylinders, servo valve controlled cylinders, mechanical self-locking and synchronous hydraulic cylinders, rotary hydraulic cylinders, special equipment cylinders for machinery, HSG series engineering cylinders, which serve the fields of aviation, aerospace, railway, electronics, petrochemical machinery, marine ships, wind power and other special mechanical equipment with users. Among hydraulic products, the company has obtained two national utility model patents (Patent No.: zl202120481656.5, zl202120481216.x).

It is our service concept to accompany you and boost the success of users!

Yu Zhang

hh08zy@163.com