In the decoration process, putty powder plays the role of primer. It mainly fills the unevenness of the wall, so that the paint or paint can be evenly applied to the wall to lay a good foundation. Putty is divided into oil-based putty and water-based putty, which are used for paint and latex paint construction. A layer of putty powder should be applied before the paint and paint application, and the paint should be applied after the putty powder is dry. Putty plays a vital role in wall decoration, and its quality is related to the success or failure of all wall decoration.

1. Interior wall putty powder: Putty powder is a one-component interior wall special putty powder refined from high molecular polymer, methyl cellulose ether and other raw materials. The putty powder produced by Lu Zhou has good firmness and bonding strength. And good waterproof ability and other characteristics, suitable for high-end places. The wall using putty powder fiber can be washed with water, without ash, without falling off, and leaving no traces after slight impact. Mix the putty powder with water for 10 minutes to form a paste-like putty and let it stand. After 5 minutes, it can be scraped on the wall in batches. Generally, it is scraped twice. When the second time is scraped, the first time the wall is dry before scraping. After drying, it should be sanded with sandpaper in time (within 24-48 hours). It is non-toxic in normal state and high temperature decomposition, and has high chemical stability.

2. Exterior wall putty powder: The putty powder is made of imported polymer redispersible rubber powder, mixed with methyl cellulose ether, modified starch ether, and anti-cracking fiber as the weight ratio (3%) of the putty powder mixture. The finished outdoor high-grade putty powder has strong resistance to the micro-cracks of the wall, and has the characteristics of good forehead viscosity, impermeability, reliability, and no shrinkage itself. The putty powder produced by Lu Zhou has good crack resistance, which greatly saves the maintenance cost of the overall strong surface. Add water and mix the exterior wall putty powder into a paste and let it stand for 5 minutes, then you can apply it to the wall in batches. Generally, the thickness should not exceed 2-3mm. It can be applied in one to three batches according to different requirements to increase its thickness. Because the exterior wall putty powder has a good water retention capacity, it can slow down the solidification and avoid the occurrence of early drying shrinkage cracks. Therefore, attention should be paid to the construction of the second layer before the first layer is dry. The construction environment temperature should not be below 5 degrees, and construction is not recommended in cloudy and rainy days.

Lu Zhou interior wall water resistant putty powder

Water-resistant putty for interior walls is a base material used for wall repair and leveling, which lays a good foundation for the next step of decoration (painting and wallpapering). Generally, ordinary putty is Y-type, and water-resistant putty is N-type.

The water-resistant putty has a better feel than ordinary putty: the surface of the water-resistant putty is smooth and delicate after construction, and the putty after finishing treatment will give people a smooth feel, and it can be used as a decorative layer with decorative effect. The unique whiteness and density of waterproof putty make the paint adhesion and coverage per unit area save 25-30% of the paint consumption compared to the wall with ordinary putty. In addition, the water-resistant putty powder requires that the product is immersed in water for 48 hours after scraping, and there is still no peeling, cracking, and bulging, and the bonding strength can reach more than 0.30Mpa. Compared with ordinary type putty, the production quality of water-resistant type putty is higher, and the cost of ordinary type is higher. The price is relatively lower than that of water-resistant putty. However, because the product is strong and sticky, it is difficult to stir and scrape, and the strength is high, and the water-resistant putty is more laborious than ordinary putty to polish. There is alkalinity before the upper wall is dry, which will produce a certain amount of alkaline calcium hydroxide, which generally lasts for 5-7 days before disappearing. At the same time, it can also decompose the color paste of the surface layer latex paint, resulting in uneven color.

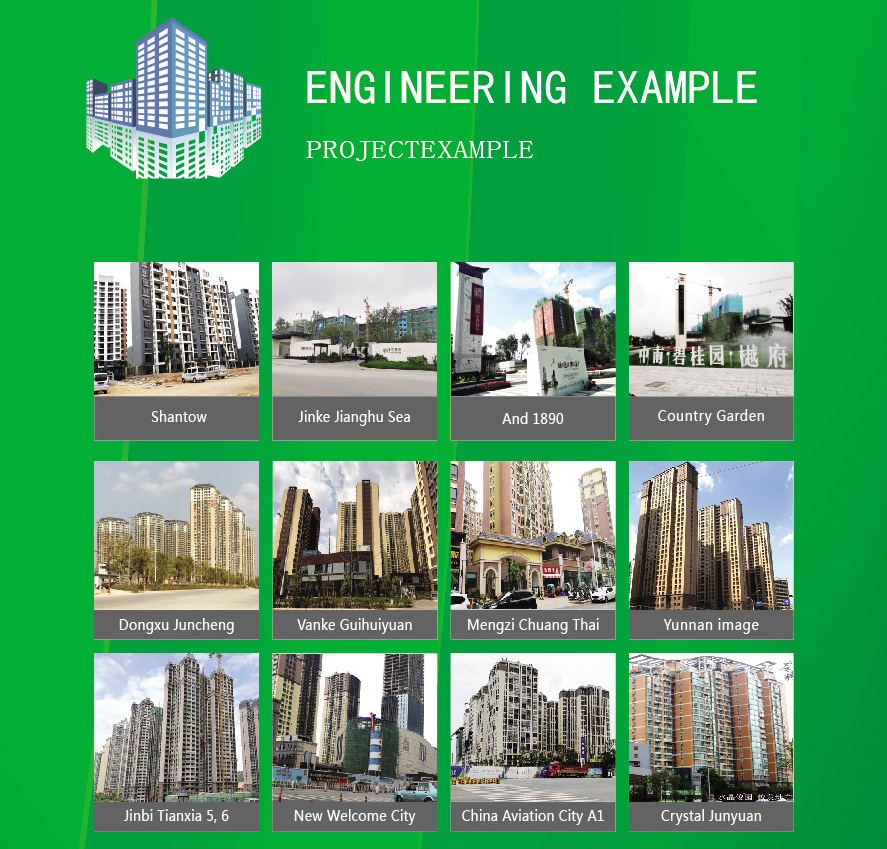

Lu Zhou Mortar is a professional manufacturer of new building materials integrating R&D, production and sales. It has established production bases in Kunming and Guiyang respectively. All raw materials are tested and qualified before entering the factory.

Lu Zhou Mortar has the ability to integrate R&D, production, testing and logistics of mortar product formulation technology. At present, it has advanced automatic production equipment such as double-shaft gravity-free mixer, storage tank, and microcomputer control room. It is currently the leading enterprise in automatic dry powder mortar production in Yunnan Province, which can achieve a daily production capacity of 300 tons and an annual output of 100,000 tons. The wall area constructed by Lu Zhou mortar products reaches 20 million square meters every year. Production products include: cement-based exterior wall putty powder series, interior wall putty series, interior wall lining series, tile adhesive series, cement self-leveling series, thermal insulation mortar series, plastering and masonry mortar series, anti-cracking mortar series, gypsum mortar series series, etc.

It is our goal to become a famous new material manufacturer in China through pragmatic innovation, integrity and unity. At the same time, we hope to beautify the living space, protect the natural environment, cooperate for win-win results and build a happy green future.

Contact Person:Li Jin

Email:1255487626@qq.com lzsj5099@gmail.com