Piocreat is an equipment manufacturer engaged in R&D, production and sales of industrial application-level 3D printers. Since its establishment in 2015, it has been committed to providing 3D printing solutions for the fields of dentistry, jewelry, automobiles, furniture, sanitary ware, etc., especially for dentistry field, following the dental LCD light curing 3d printer DJ89, D128, Piocreat recently launched their DLP 3D printer Pionext D150.

In the official release, the Piocreat Pionext D150 has made its debut, using the latest DLP chip from Texas Instruments (TI), which means it will provide higher-quality printing with lower power consumption. Its overall design is relatively simple and technological, with dimensions (330 × 300 × 675 mm), and it supports a maximum length, width and height of 144 × 81 × 100 mm for models. Pionext D150 supports a layer thickness of 0.025~0.1 mm, a printing speed of 1-4s/layer (max. 30mm/hour), and a native optical resolution of 1980×1080. Compared with SLA and LCD 3D printers, DLP 3D printers not only have advantages in detail, power consumption, lifespan, etc., but also require less maintenance with more stable printing.

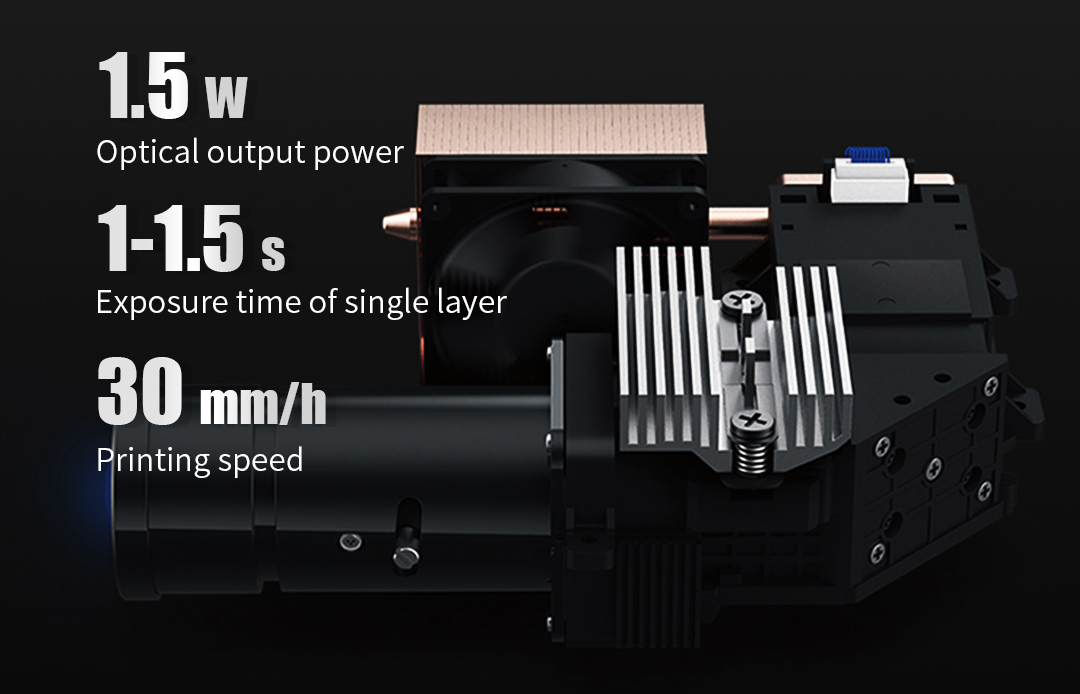

It is reported that the Pionext D150 uses a new chip from Texas Instruments (TI), with the newly developed optical machine, it can print at a high-precision resolution of 1080P. The software algorithm is optimized, and the system has its own distortion compensation to ensure that the opto-mechanical projection is a regular rectangle. The light output power of D150 is 1.5w, the single-layer exposure time is 1-1.5s, and the printing efficiency is higher. In addition, compared with LCD, there is no heating of the printing screen, which does not affect the expansion rate of the resin, and the printing is more stable.

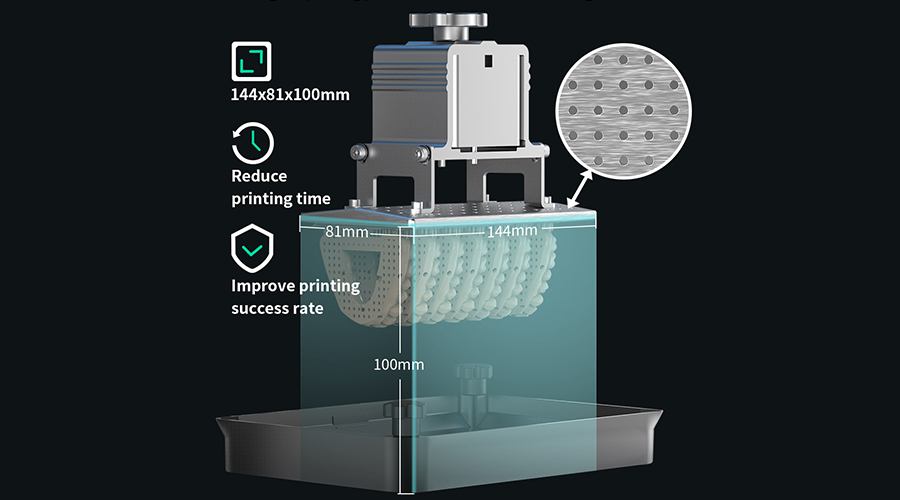

It is worth mentioning that the Pionext D150 has carried out a subversive innovation on the forming platform, and adopts the surface sandblasting oxidation belt hole design. The high sandblasting roughness of the surface of the platform can increase the contact area of the printing model, and the adhesion will be stronger during the printing process, and it will not fall off easily. With holes to speed up platform drainage and backflow during printing. This shortens the printing time and improves the printing success rate.

Piocreat D150 continues the high-precision dual linear guideway + ball screw combination structure of the Pionext series. The ball screw has its own lubrication function to ensure the stability of the Z-axis and the quiet and smooth movement, and the platform will not shake left and right. With 57 stepping motor, the torque is large, no step is lost, the release force is sufficient when printing, and the printing success rate. In addition, in terms of the printing platform, the multi-layer composite material release technology is innovatively adopted. When the surface is smooth and printed, the release resistance is small, and the mold can be taken instantly after cured.

The Piocreat Pionext D150 also performs well in terms of environmental protection. It has a built-in automatic air purification system and an air-cooled heat drive design. During the operation of the machine, the light source screen and the machine can be cooled and ventilated. With activated carbon air filtration system, it can absorb most of the resin odor, bringing users a refreshing and comfortable printing experience.

More intimately, the operating system of Piocreat Pionext D150 also supports 14 languages, providing flexible language switching for users in major global markets. The slicing software comes with a parameter package, which can realize one-click slicing, simple operation, and is compatible with all 405nm resins on the market.

Company:Shenzhen PioCreat 3D Technology Co., Ltd.

Contact Person:Jerry Luo

Email:sales@piocreat3d.com

Website:www.piocreat3d.com

Telephone:+86 19925217796

City:Shenzhen