Through a strong equipment base and experienced technical support, Forman has established long-term cooperative relationships with many world-renowned companies and become their first-tier suppliers. Forman always insists on providing high-quality auto parts, injection stamping parts, electronic connectors, and looks forward to working with you in the future for mutual development and mutual benefit.

It has a mold manufacturing workshop, an injection molding workshop, a stamping workshop, an assembly workshop, and advanced equipment to complete processes such as EDM and wire electrode cutting. We have 25 injection molding machines from NISSEI and Fanuc, ranging from 30T to 180T, equipped with robotic arms, and vertical injection molding machines with CCD inspection cameras. The press shop has 24 high-speed presses ranging from 35T to 110T, including machines such as Kyori and Yamada, all covered by protective casings for safety. All machines in the assembly shop are designed and built by our team to automate the assembly process, inspection and packaging, providing high productivity and consistent quality.

production capacity

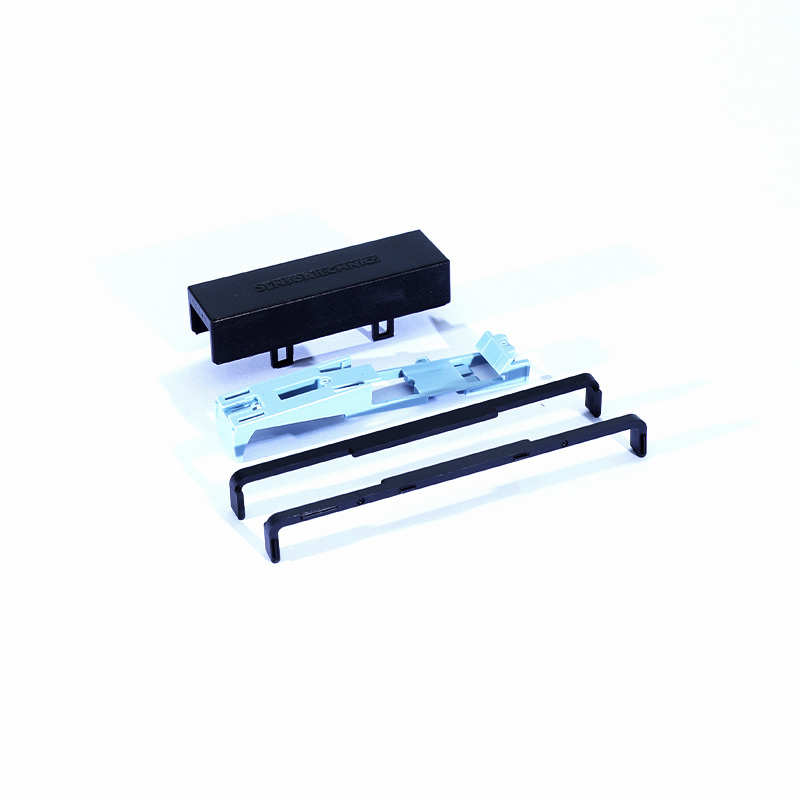

For precision injection molding process, we have rich experience in production and development of automotive casings, consumer electronic parts, etc. Mainly deal with PA66, PA6T, PA9T + glass fiber, LCP, PBT, ABS and other materials.

In terms of precision stamping process, all our machines are high-speed punching machines, which use continuous stamping technology, which greatly improves the quality of parts and production efficiency. We specialize in metal terminals, housings, heat sinks, contact pins, etc. in the fields of automotive, electronics, aerospace, etc.

Product performance: 10 years CNC machine metal and non-metal high precision fast delivery

Non-standard customized processing of various mechanical parts, metal or non-metal precision instrument shells and other accessories

Business scope: household appliances, medical equipment, auto parts, Donggefei, industrial electronics, intelligent robot communication

auto auto precision electrical parts oem manufacturer plastic mould parts

Zeya is committed to optimizing factory strength, improving quality control system, and enriching R&D capabilities to meet greater challenges and meet different requirements. At present, our products are widely used in consumer electronics, automotive industry, testing instruments and other fields

1. There are vertical and horizontal injection molding machines.

2. Provide one-stop manufacturing services from mold design, manufacturing, assembly, and delivery.

3. Short delivery time, but fast response.

4. Various professional materials.

5. Strong R&D support, quality assurance

Since 2006, it has passed ISO9001, ISO14000, IATF16949 certification, and has achieved fully automatic production in precision injection molding, insert molding, stamping, and assembly services. In order to provide high-precision products and high productivity, we have introduced many equipments, such as Sodick slow-feed CNC wire cutting machine, Kyori and Yamada Punch, Fanuc injection molding machine, etc.

At the same time, we value high technical ability and employ experienced technical and management personnel with sophisticated technology and high quality. In addition, Forman has established an independent testing laboratory in China, which can quickly complete environmental, electrical, mechanical, salt spray and other tests

The registered address of Chengdu Zeya Technology Development Co., Ltd. is located at No. 4208, Xiyuan Avenue, South District, Chengdu Modern Industrial Port, Pi County, Chengdu. The registration authority is Pidu District Market Supervision and Administration Bureau, and the legal representative is Liu Ningquan. R&D, design, production, and manufacture of products (excluding rare and precious metals), medical equipment, electronic products, and electromechanical equipment; sales: electromechanical products, steel, non-ferrous metals (excluding precious metals), Wujinjiaodian, plastic products, metal products (excluding rare and precious metals), medical equipment, electronic products; mechanical and electrical equipment leasing and technical consulting services; import and export of goods and technologies. (For projects subject to approval according to law, business activities can only be carried out after approval by relevant departments).

Deng Xiaolan

XiaolanDeng79@gmail.com

liunq@zeyatech.com