1.The solenoid valve from the principle is divided into three main categories.

Direct-acting solenoid valve

Principle: When energized, the solenoid coil generates electromagnetic force to lift the closing piece from the seat, the valve opens; when disconnected, the electromagnetic force disappears, the spring presses the closing piece on the valve seat, the valve closes.

Features: can work normally in vacuum, negative pressure, zero pressure, but the passage diameter is generally not more than 25mm.

Step-by-step direct-acting solenoid valve

Principle: It is a combination of direct-acting and piloting principles. When there is no pressure difference between inlet and outlet, after energizing, the electromagnetic force directly lifts the pilot small valve and main valve closing member upward in turn, and the valve opens. When the inlet and outlet reach the start pressure difference, after energizing, the electromagnetic force pilot small valve, the main valve lower chamber pressure rises, the upper chamber pressure drops, thus using the pressure difference to push the main valve upward; when the power is off, the pilot valve uses the spring force or medium pressure to push the closing member and move downward to close the valve.

Features: in zero differential pressure or vacuum, high pressure can also be * action, but the power is large, requiring horizontal installation.

Pilot operated solenoid valve

Principle: When energized, the electromagnetic force opens the pilot hole, the pressure in the upper chamber drops rapidly, forming a low pressure differential around the closing member, the fluid pressure pushes the closing member to move upward, the valve opens; when de-energized, the spring force closes the pilot hole, the inlet pressure through the bypass hole quickly chamber around the closing member to form a low pressure differential, the fluid pressure pushes the closing member to move downward, closing the valve.

Features: fluid pressure range upper limit is high, can be installed at will (need to customize) but must meet the fluid pressure differential conditions.

2.Solenoid valve from the valve structure and material differences and principles, divided into six branches of subcategories: direct-acting diaphragm structure, step-by-step direct-acting diaphragm structure, pilot diaphragm structure, direct-acting piston structure, step-by-step direct-acting piston structure, pilot piston structure.

3.Solenoid valve according to functional classification: solenoid valve for water, steam solenoid valve, refrigeration solenoid valve, low temperature solenoid valve, gas solenoid valve, fire solenoid valve, ammonia solenoid valve, gas solenoid valve, liquid solenoid valve, mini solenoid valve, pulse solenoid valve, hydraulic solenoid valve normally open solenoid valve, oil solenoid valve, DC solenoid valve, high pressure solenoid valve, explosion-proof solenoid valve.

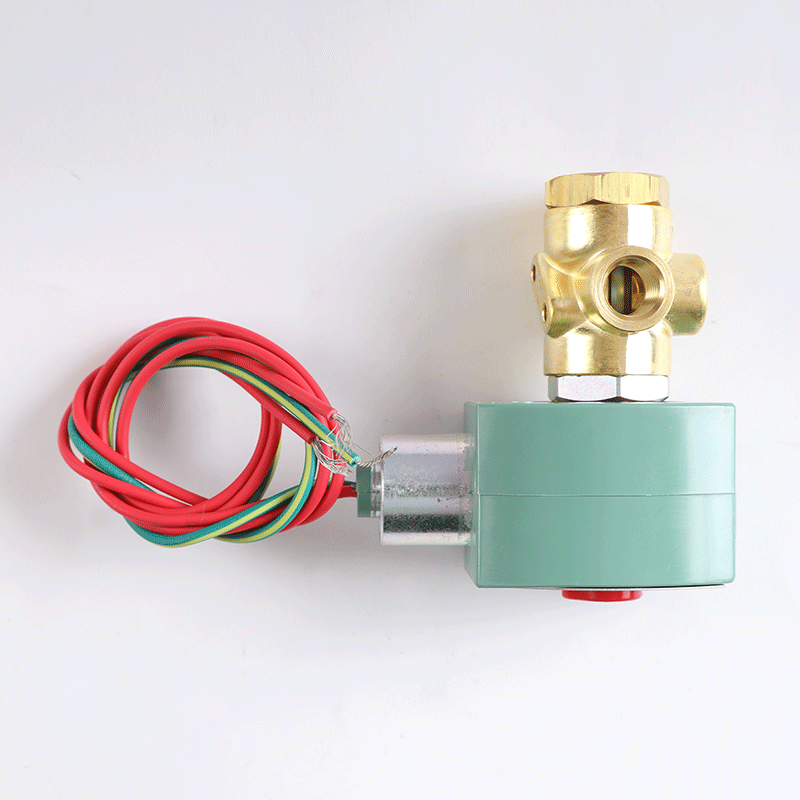

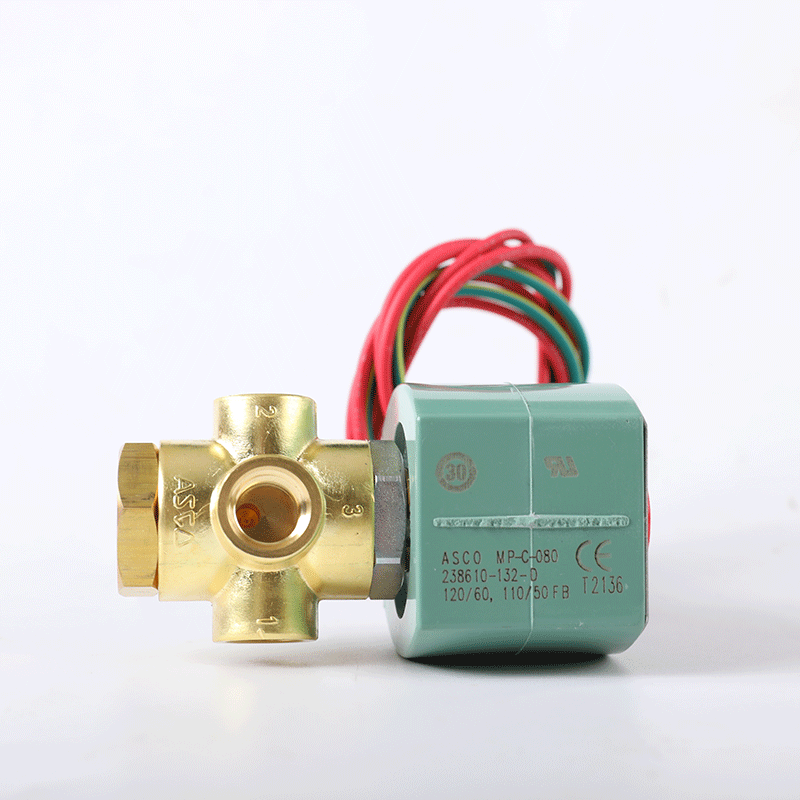

Solenoid valve (Solenoid valve) is an industrial equipment controlled by electromagnetism, is used to control the fluid automation basic components, belongs to the actuator, and is not limited to hydraulic, pneumatic. It is used in industrial control systems to adjust the direction, flow, speed and other parameters of the medium. Solenoid valves can be used with different circuits to achieve the desired control, while the accuracy and flexibility of the control can be guaranteed. There are many kinds of solenoid valves, different solenoid valves function in different positions of the control system, the most commonly used are one-way valves, safety valves, directional control valves, speed adjustment valves, etc.

Solenoid valve has a closed cavity, in different locations open holes, each hole connected to a different oil pipe, the middle of the cavity is the piston, the two sides are two electromagnets, which side of the magnet coil energized valve body will be attracted to which side, by controlling the movement of the valve body to open or close the different drain holes, and the inlet hole is always open, the hydraulic oil will enter the different drain pipes, and then through the pressure of the oil to push the piston of the cylinder, and the piston drives the piston rod, the piston drives the piston rod, and the piston drives the piston. The piston in turn drives the piston rod, and the piston rod drives the mechanical device. In this way, mechanical movement is controlled by controlling the current flow of the solenoid.

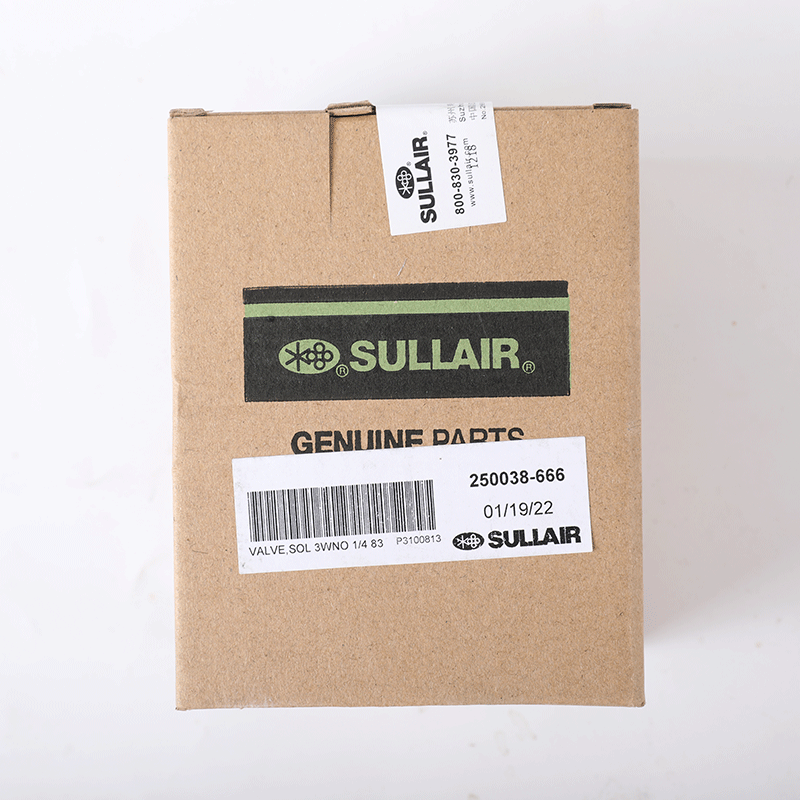

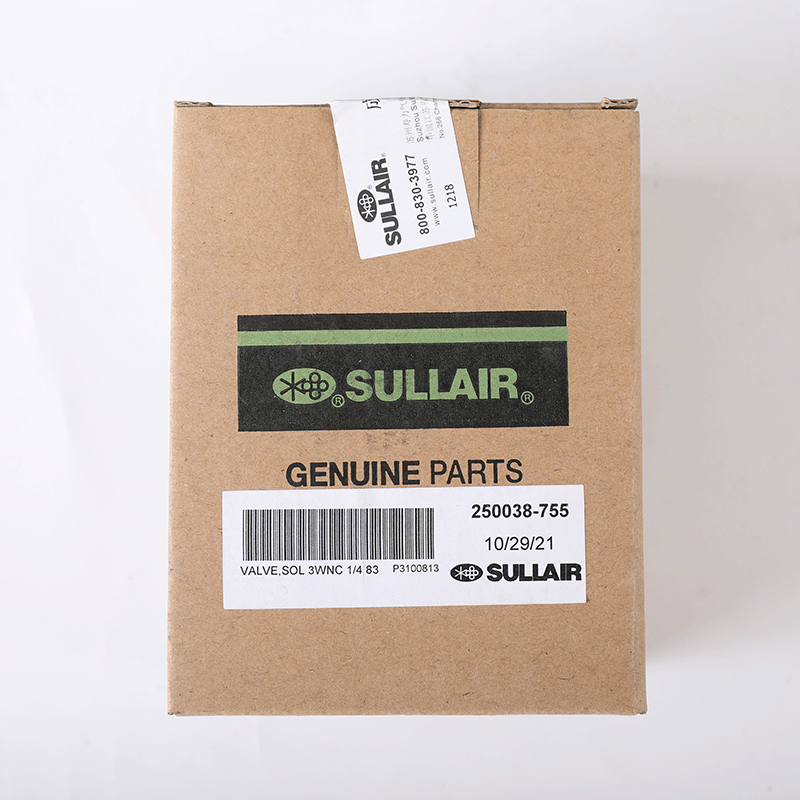

Chengdu Haobesen Electromechanical Equipment Co., Ltd. was incorporated on December 18, 2018, and is engaged in the maintenance, installation, leasing, and technical consultation of electromechanical equipment; sales: electromechanical equipment and its accessories, lubricants, computer software, hardware and accessories, electronics Products, instrumentation, Wujinjiaodian, chemical products (excluding dangerous goods), building materials, metal materials, etc. On March 28, 2019, it became a legal distributor jointly authorized by Sullair Asia Industrial Co., Ltd. and Suzhou Sullair Gas Equipment Co., Ltd. The company's sales, technology, service and company management team members are all from the original Sichuan first-class agent of Sullair. At present, the company has 12 employees, including 2 A-level service engineers and 1 B-level service engineer authorized by Sullair.

Company tenet: Sullair is quality, Sullair is service. Company business: 1. Comprehensive sales of Sullair air compressors, vacuum pumps, and drying filtration equipment; 2. Provide various genuine accessories and consumables for Sullair customers; 3. Provide technical support and standardized after-sales service for Sullair customers.

He Daixiang

cdhbsjd@gmail.com