Tee joint is a kind of pipe fittings, its connection form is to directly weld the tee to the steel pipe, the main manufacturing standards for tee joints are generally GB/T12459, GB/T13401, ASME B16.9, SH3408, SH3409, HG/T21635, HG/T21631, SY/T0510. tee joint forming is to take a pipe billet larger than the tee The billet diameter, flattened to about the size of the diameter of the tee, a hole is opened in the part of the stretching branch; the billet is heated, put into the forming die, and the punching die for stretching the branch is installed in the billet; the billet is compressed radially under pressure, and the metal flows in the direction of the branch during the process of radial compression and forms the branch under the stretching of the punching die. The whole process is formed by the radial compression of the billet and the stretching process of the branch part. Unlike the hydraulic expansion tee, the metal of the tee fitting stub is compensated by the radial movement of the billet, so it is also called the radial compensation process. The tonnage of the equipment required for material forming is reduced due to the use of heated and then pressed tees. The adaptability of hot pressing tee to materials is wide, and it is suitable for materials of low carbon steel, alloy steel and stainless steel; especially for large diameter and tee with thick wall, this forming process is usually used.

Classification

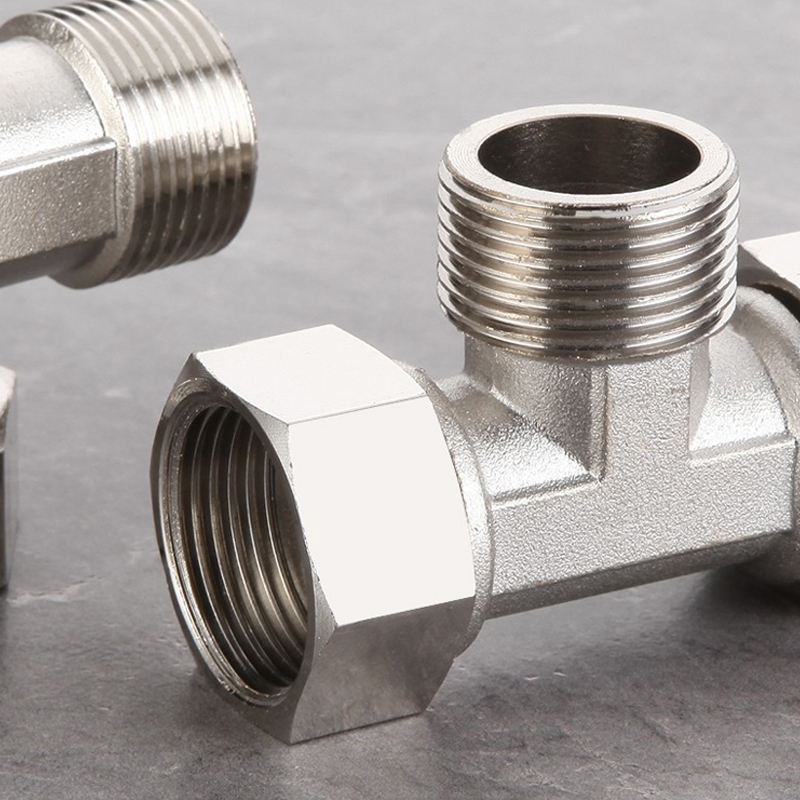

1、According to the caliber of pipe fittings, there are generally equal tee, reducer tee, etc.

2、According to the direction of the branch pipe is divided into positive tee and oblique tee.

3、According to the material points have carbon steel, alloy steel, stainless steel, copper, PVC and other tees.

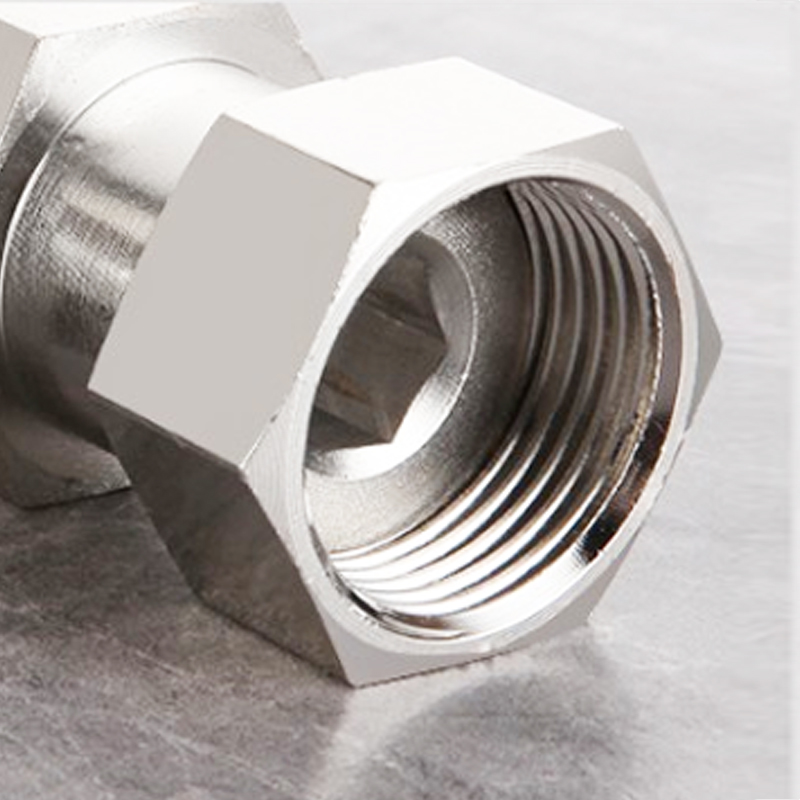

4、According to the connection method, there are common tee, threaded tee, ferrule tee, socket tee.

5、The tee is expressed as follows: for equal diameter tee, such as ""T6"" tee means the outside diameter is 6 inches equal diameter tee.

Divided by material.

Carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon chrome leaching, PVC, etc.

Divided by production method.

Top, press, forging, casting, etc.

Established in 2015, Chengdu Ankeda Trading Co., Ltd. is located in Chengdu, Sichuan Province, China. In the 7 years of the company's development and growth, we always provide customers with good products, good technical support, sound after-sales service, our company is mainly engaged in the sale of: hardware products, machinery and equipment and accessories, etc." Management to create value, service to enhance the advantages, quality first, service to the best" is the development concept of the company. Unity, innovation, pragmatism and advancement are the company's unswerving pursuit. The company treasures every point of honor, insists on the business purpose of "quality first, customer supreme, prosperous with quality, winning with excellence", constantly contributes excellent products to the society, and creates brilliance together with all sectors of the society with complementary advantages!

Gong Guofeng

787286963@qq.com